installation of pot bearing

Pot bearing installation

1.Checking the pot bearing parameter information

Before installing pot bearings, check the package and nameplate of the products, including loading capacity, model, types and displacement of the pot bearing, to make sure it is right product to be installed. And check if the temporary connections and ruler pointers are intact.

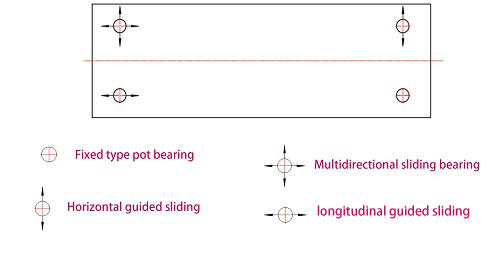

2.Confirm the installation point of each pot bearing.

3.Installation of pot bearing on the beam bottom

1),After installing the pot bearing at the bottom of the beam, tighten the connecting bolts or nuts!

2),Be sure to use anti loosening spring washers!

3),Please note that there must be no gap between the pot bearing top plate and the embedded steel plate at the bottom of the beam! If gap existed, it must be adjusted

.jpg)

4. Pier cushion stone

20-30mm thickness Non shrinkage dry hard mortar must be placed on the surface of pier cushion stone, The surface height difference after compaction should be less than 2mm, And pay attention that the mortar around the reserved hole should not exceed the horizontal plane.when there are two pot bearings are installed on the horizontal direction, the height of cushion stone should be the same on the horizontal direction of the two bearings

5, The work of reserved holes

The reserved holes must be worked according to drawing requirement, the depth and diameter of reserved holes must larger than embedded length and diameter of the support sleeve or bottom column,Generally, it is advisable to have a diameter and depth greater than 60mm, and clean up any debris.

6.Precautions for beam dropping operation

When dropping the beam, it must be stable, and the pot bearing at both ends of the beam should be put on the pier and abutment at the same time, to avoid the occurrence of a single support contacting the pier and abutment, which may cause abnormal displacement of the pot bearing due to eccentric force. When the beam is dropped, the embedded bolts of the pot bearings should be avoid contacted with the surface of the cushion stone outside the embedded hole to prevent the pot bearing from being subjected to horizontal force and causing abnormal displacement.

7.Precautions of grouting

1), After the pot bearing of T - beam is in placed, when the bolts holes are poured , the holes must be poured in one time to prevent layering of the upper and lower layers of concrete during two pours.

After pouring is completed, check if there is any leakage of grout and seal the dry and hard mortar joints around the pot bearing. If there is a gap between the pot bearing bottom plate and the mortar, it must be filled with grout.

2), When pouring the box girder pot bearing in place, attention must be paid to the amount of grouting material used. During pouring, the grouting material should flow from the center of the bottom of the support to the surrounding areas to prevent incomplete or empty pouring of the lower part of the pot bearings.

9, Remove The Temporary Connections

When dismantling temporary connections, if gas cutting is required, the flame should be cut from the inside to the outside of the pot bearing to avoid damaging the pot bearing .

Inquiry for Our Product

Zaoqiang Dacheng Rubber Co., Ltd.

E-mail:

sales@bridgebearing.org

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.